SHEET METAL FABRICATION

SHEET METAL FABRICATION – Precision in Every Fold

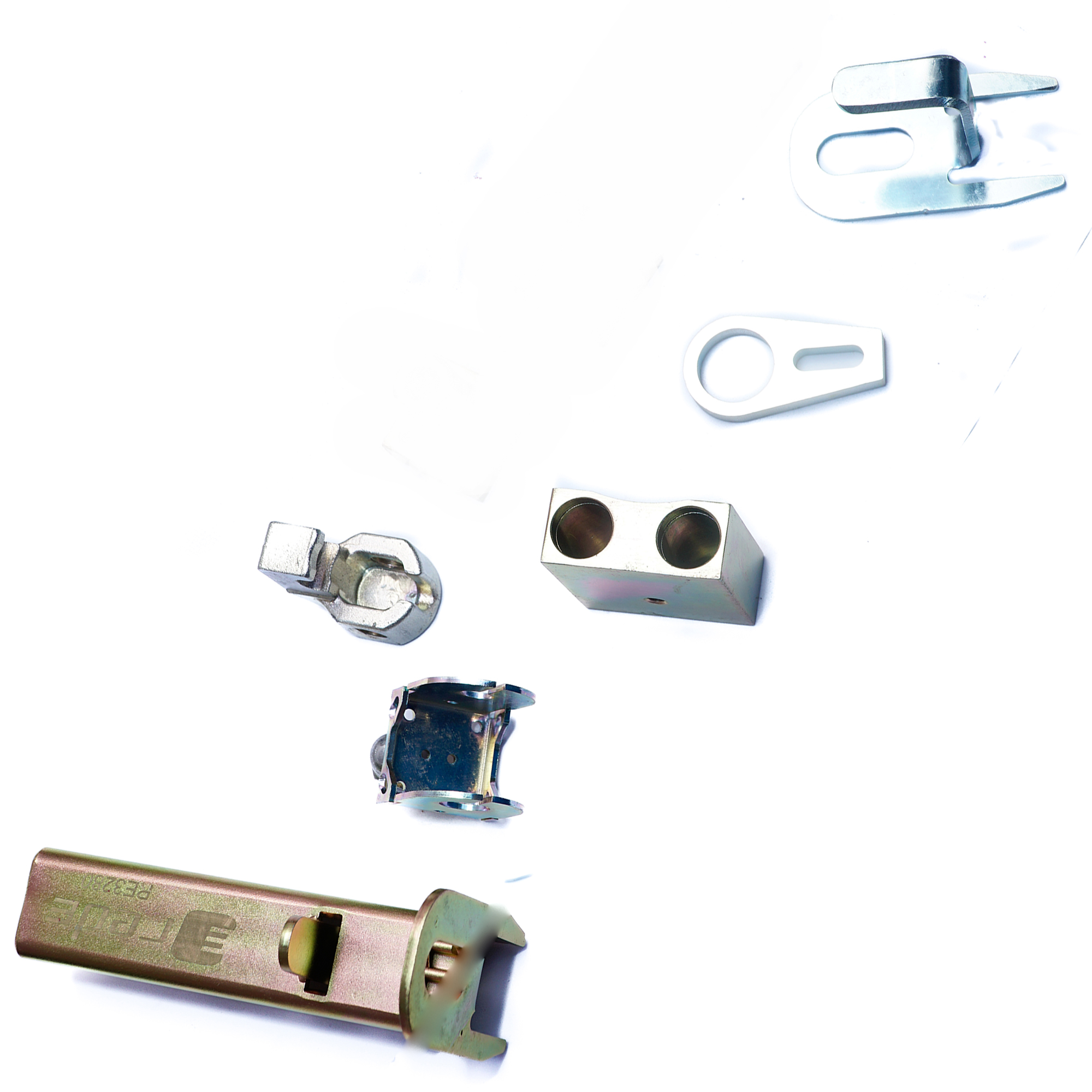

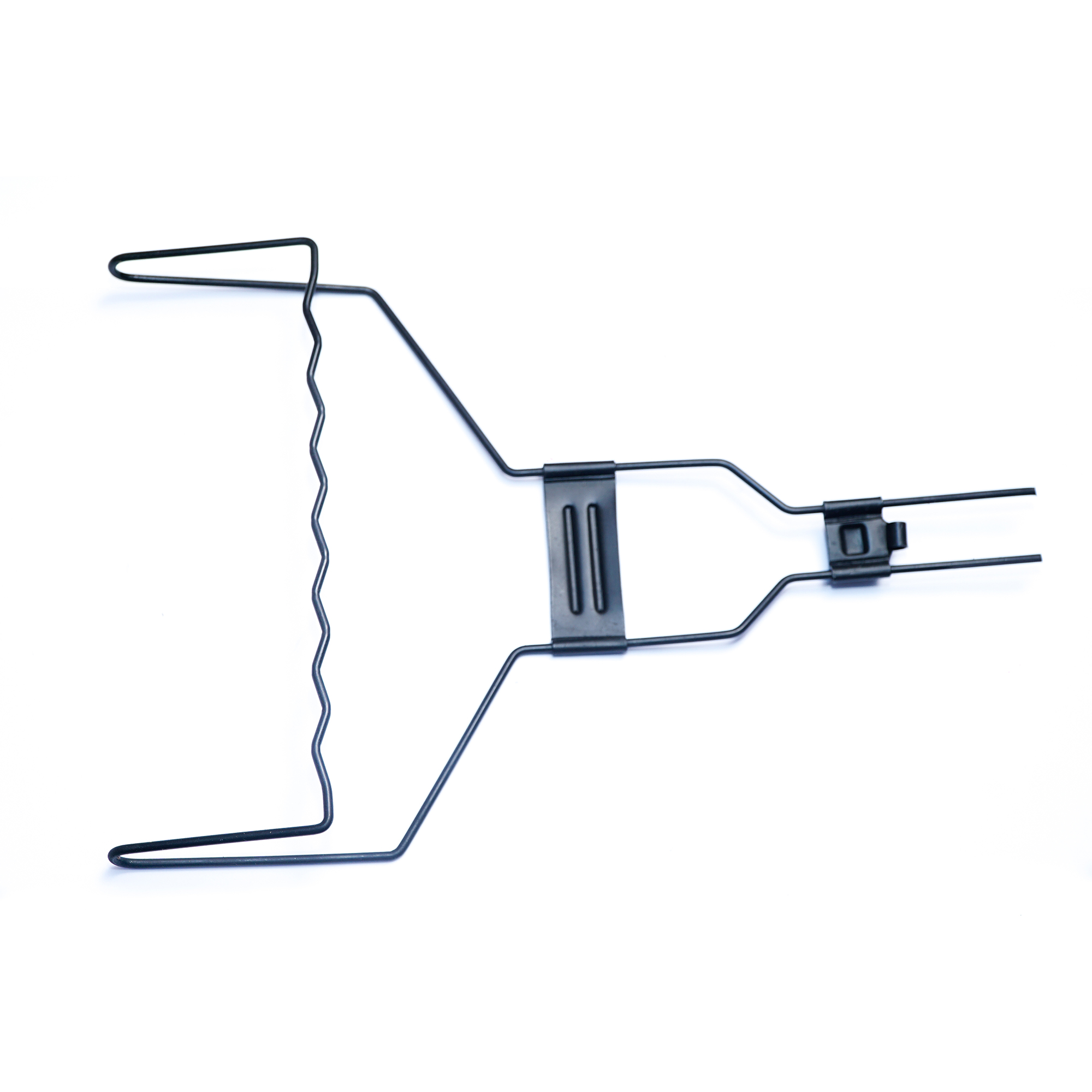

Sheet Metal Fabrication is a core manufacturing process where flat metal sheets are transformed into functional parts through cutting, bending, punching, and assembling. At ONE SOURCE ENGINEERS, we offer full-spectrum sheet metal fabrication services using a combination of manual expertise and CNC-powered precision tools to create high-quality, durable, and dimensionally accurate components.

Our solutions are tailored for diverse industries including automotive, electrical enclosures, construction, industrial machinery, HVAC, and aerospace. With 60+ vendor partners under one roof, we can deliver everything from simple brackets to complex enclosures—at speed and scale.

Why Choose ONE SOURCE ENGINEERS for Sheet Metal Fabrication?

OUR ENGINEERING CAPABILITIES

1. LASER CUTTING

Laser cutting uses high-powered lasers to cut precise shapes out of sheet metal. It allows intricate designs and clean edges, reducing the need for post-processing.

2. PLASMA CUTTING

Plasma cutting uses an accelerated jet of hot plasma to cut conductive metals. It is more cost-effective for thicker sheets and heavy-duty industrial parts.

3. WATERJET CUTTING

Waterjet Cutting is a high-pressure, cold-cutting technology that uses a fine stream of water mixed with abrasive materials (like garnet) to cut through metals, composites, stone, and other materials with extreme accuracy and no heat distortion.

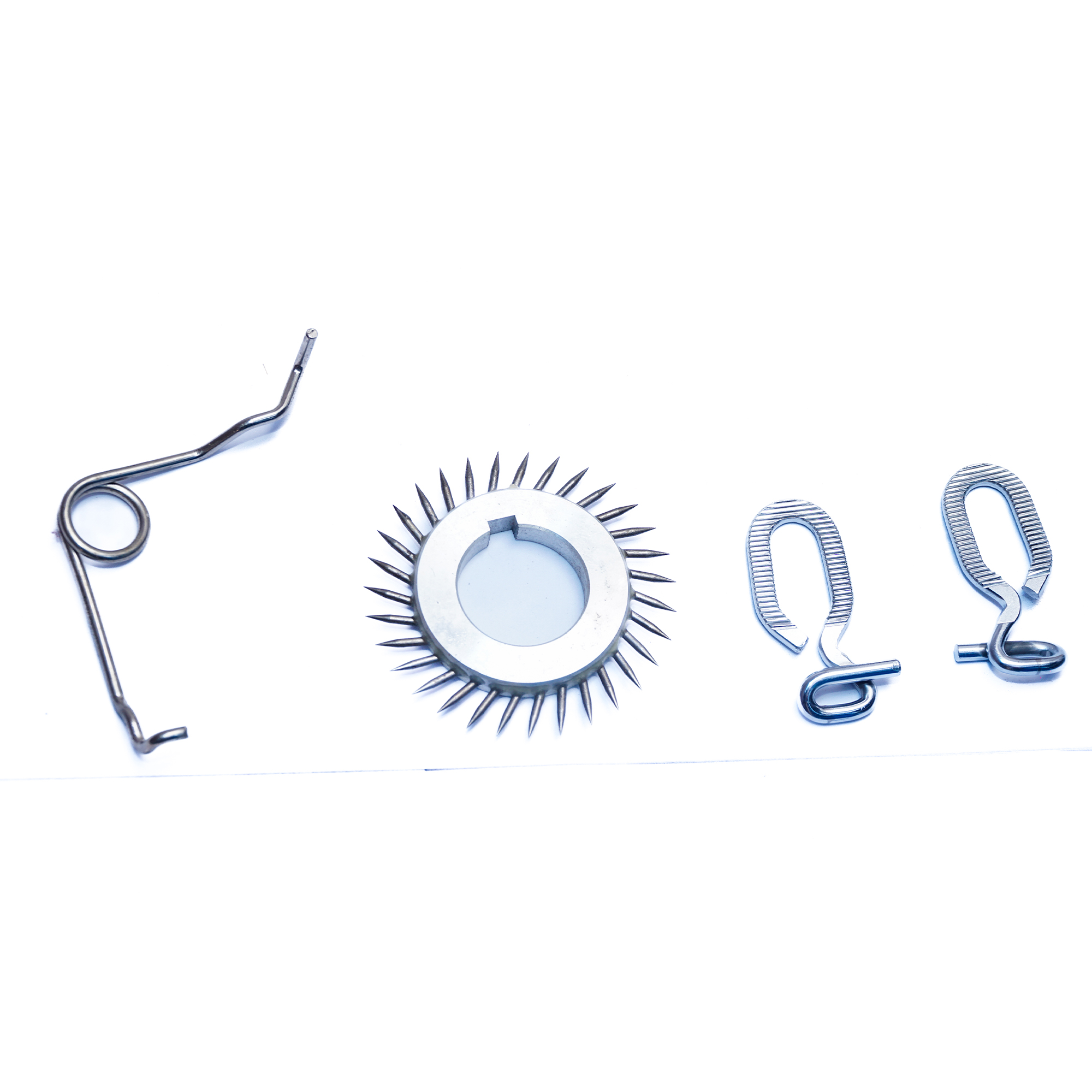

4. WIRE CUTTING

Wire EDM (Electrical Discharge Machining), also known as Wire Cutting, is a non-contact process that uses a thin electrically charged wire to erode material and create extremely accurate, complex shapes—even on hardened materials.