PLATING WORKS

PLATING WORKS – Surface Perfection, Engineered to Perfection

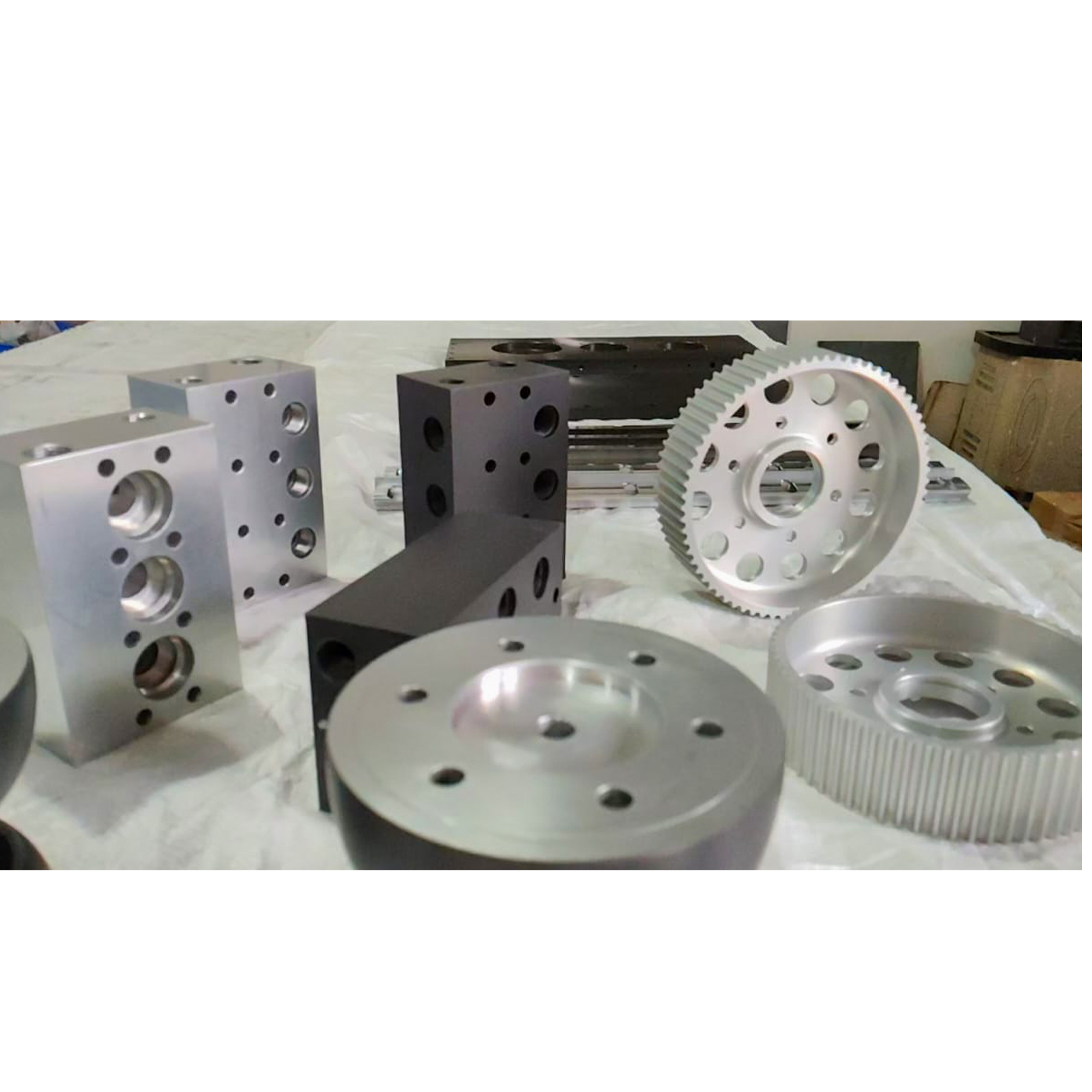

Plating and surface finishing are essential in precision manufacturing, serving both functional and aesthetic purposes—such as corrosion protection, wear resistance, electrical conductivity, and improved surface appearance. At ONE SOURCE ENGINEERS, we offer a comprehensive range of industrial plating and coating services that enhance the performance, lifespan, and appearance of components across various sectors.

With our in-house setup and partner network, we ensure that every component receives the correct surface treatment based on the metal type, application, operating environment, and customer specifications.

Why Choose ONE SOURCE ENGINEERS for Plating Works?

✅ Access to diverse plating processes under one roof

✅ Strict quality control for thickness, adhesion, and corrosion resistance

✅ RoHS & REACH-compliant finishes for export-grade requirements

✅ Suitable for high-volume production and precision batches

✅ Pre-treatment, masking, and post-process inspection available

OUR ENGINEERING CAPABILITIES

1. Chromate Coating

Chromate coating is a conversion coating applied to zinc, aluminum, or magnesium surfaces. It enhances corrosion resistance and promotes paint adhesion. Often used after zinc plating.

2. Anodizing

Anodizing is an electrochemical process that converts the aluminum surface into a thick, corrosion-resistant oxide layer. It’s available in decorative and hard anodizing types.

3. Hard Nickel Plating

Hard Nickel Plating deposits a uniform layer of nickel-phosphorus alloy on the component, offering superior wear resistance, hardness, and corrosion protection without electrical current.

4. Powder Coating

Powder Coating is a dry finishing process where a thermoset or thermoplastic powder is electrostatically sprayed and then heat-cured on the metal surface to form a tough, uniform layer.

5. Hard Dip Galvanizing

Hard Dip Galvanizing involves immersing components in molten metals or polymer-based coatings to form a thick, protective layer. It’s used for corrosion resistance and electrical insulation.

6. Hard Nickel Coating

Nickel Coating, also known as Nickel Electroplating, deposits a nickel layer on metal surfaces using an electrical current. It provides a bright finish, corrosion protection, and surface hardness.