MACHINE SHOP

MACHINE SHOP – Precision Engineering

At ONE SOURCE ENGINEERS, our advanced Machine Shop is the heart of our precision manufacturing. We combine skilled machinists, strict quality standards, and cutting-edge CNC infrastructure to deliver tight-tolerance components for automotive, aerospace, oil & gas, defense, and industrial machinery sectors.

With 60+ trusted vendor partners and state-of-the-art equipment under one roof, we offer end-to-end machining solutions—from prototyping to mass production.

Why Choose ONE SOURCE ENGINEERS for Machining?

- Full-service machining under one roof

- Advanced multi-axis equipment

- CAD/CAM integration for faster lead times

- Highly experienced operators and QA experts

- Support for prototype, low-volume, and mass production

- Industry-compliant documentation and traceability

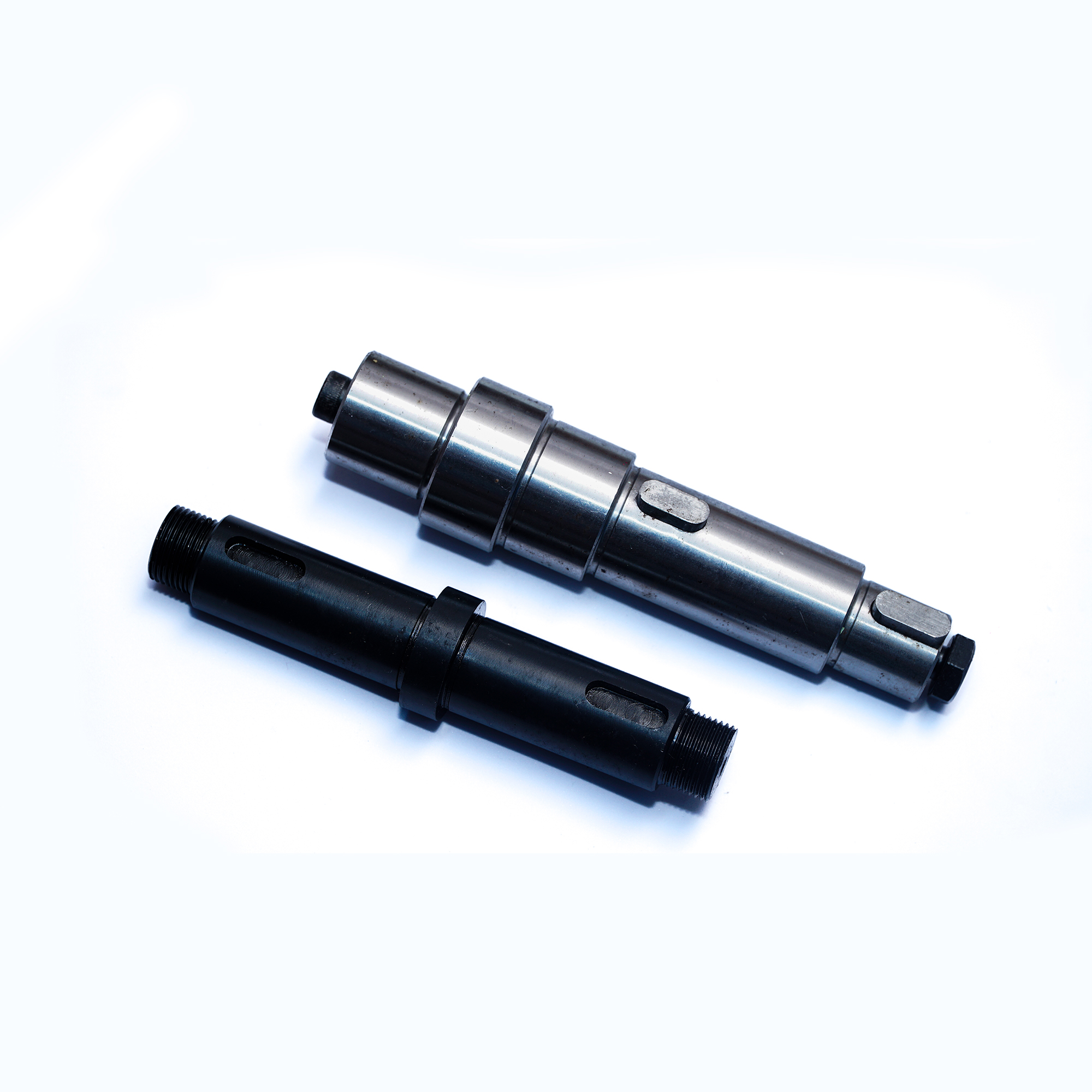

CORE MACHINING CAPABILITIES

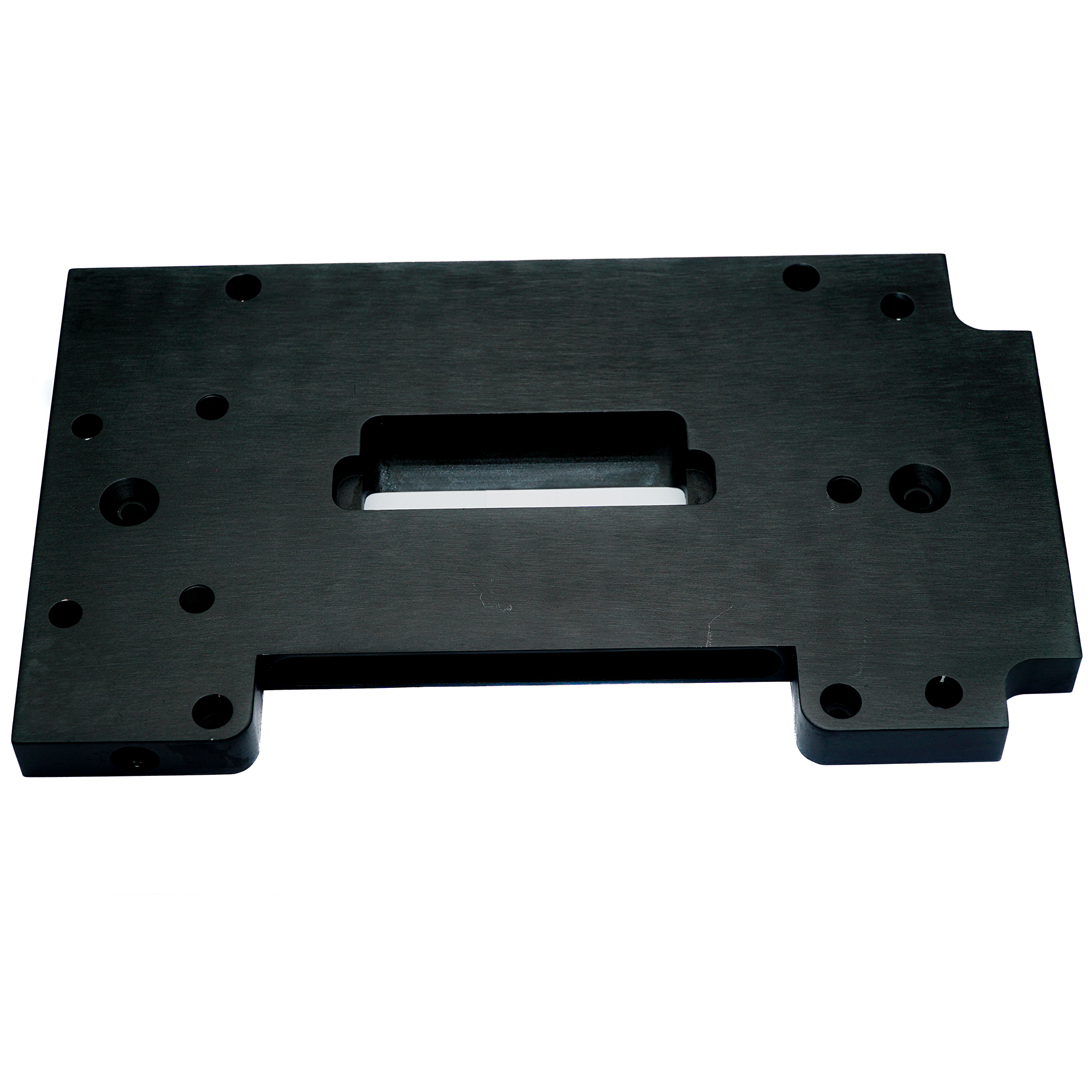

1. CNC Machining (Computer Numerical Control)

Our CNC machines enable accurate, repeatable, and complex machining operations with exceptional consistency. Ideal for both ferrous and non-ferrous metals.

Axis range: 3-axis, 4-axis, and 5-axis CNCs

Accuracy: Up to ±0.01 mm

Suitable for: Milling, turning, drilling, threading, and boring

2. VMC (Vertical Machining Center)

Our VMCs are tailored for vertical axis precision and high-speed operations, ideal for moulds, tools, and detailed surface machining.

Complex 3D machining

Multi-tool automatic changers

Suitable for: Aerospace parts, dies, auto components

3. HMC (Horizontal Machining Center)

For multi-face machining and heavy component production, our HMCs offer excellent chip removal, higher stability, and lower cycle times.

Ideal for batch production

Reduces repositioning

Suitable for: Engine blocks, pump housings, gear casings

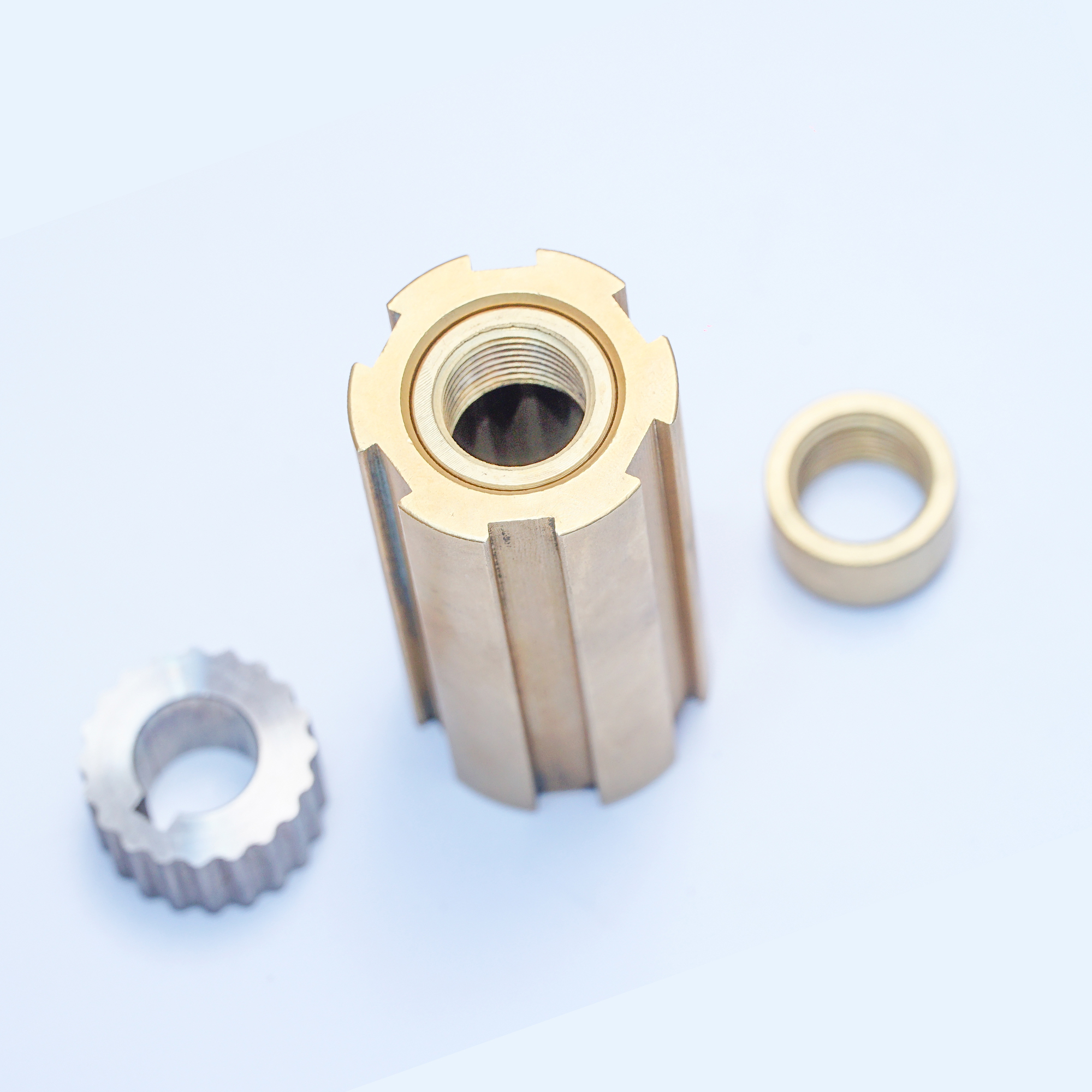

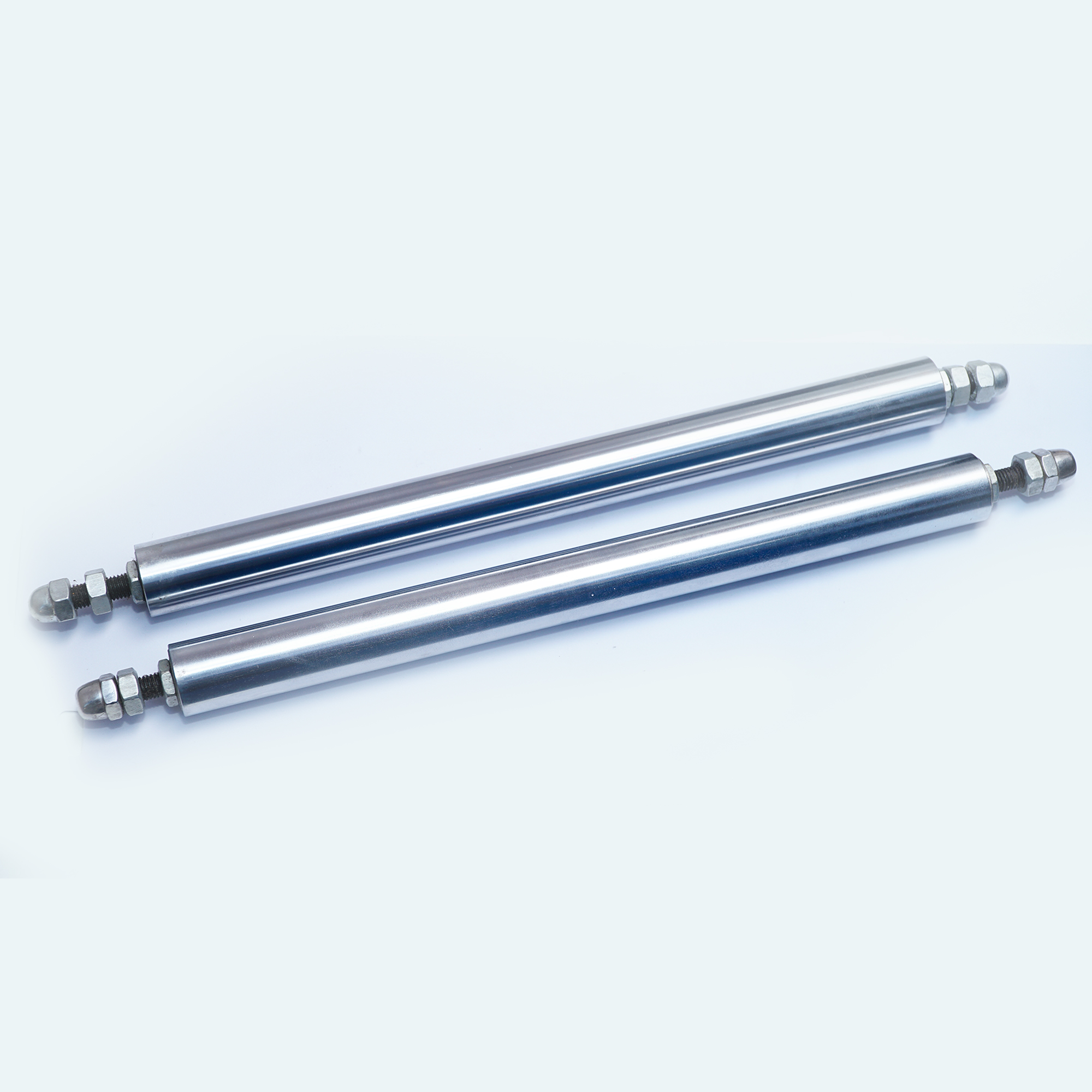

4. VTL (Vertical Turning Lathe)

VTLs are specialized for large, heavy, and cylindrical components with high concentricity.

High rigidity, vertical clamping

Ideal for: Flanges, wheels, large rings, aerospace discs

ADDITIONAL CAPABILITIES

1. Surface Grinding

We offer fine surface finishing with tight flatness and parallelism on critical components. Our surface grinders are calibrated for parts that require high precision finishing.

Flatness up to 0.003 mm

Smoothness for sealing, bearing, and mating surfaces

Suitable for: Dies, jigs, gauges, and sliding surfaces

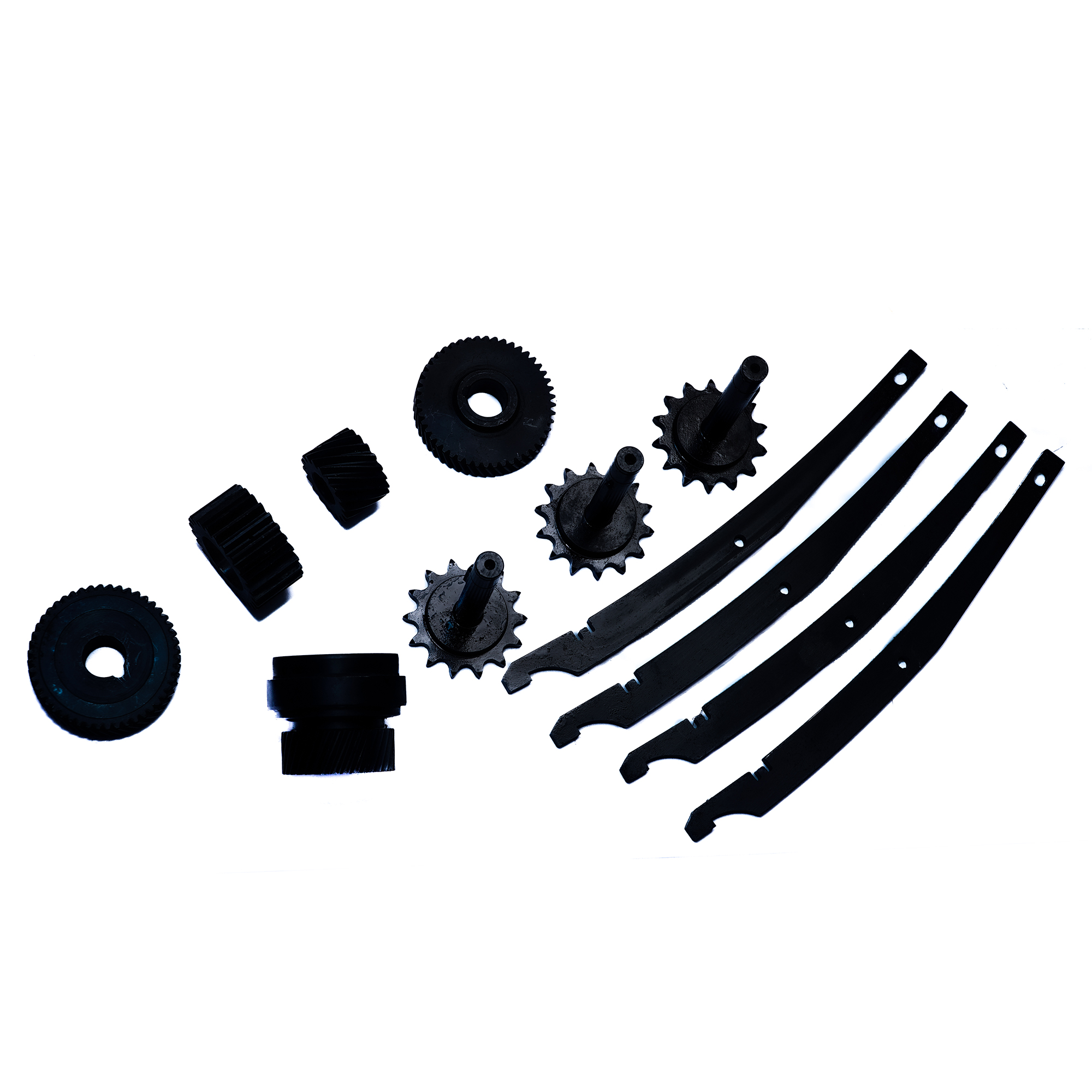

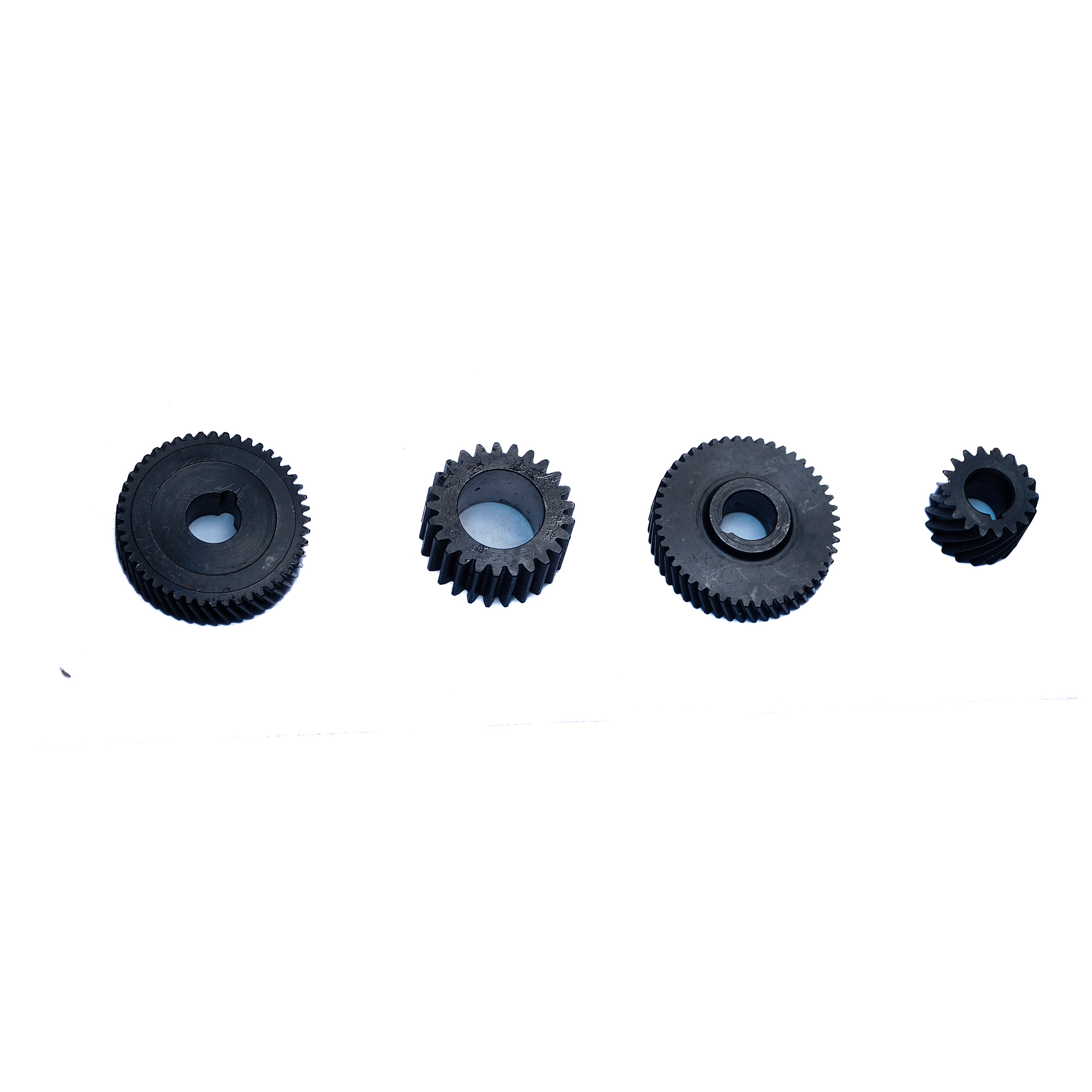

2. Gear Cutting

From spur gears to bevel gears, our gear cutting services ensure dimensional accuracy, smooth operation, and long life. We handle small to large-volume requirements with in-house inspection.

Types: Spur, Helical, Worm, Bevel

Profile grinding & hobbing available

Applicable in: Transmission, agriculture, heavy equipment industries