CASTING

CASTING – Precision Begins at the Mold

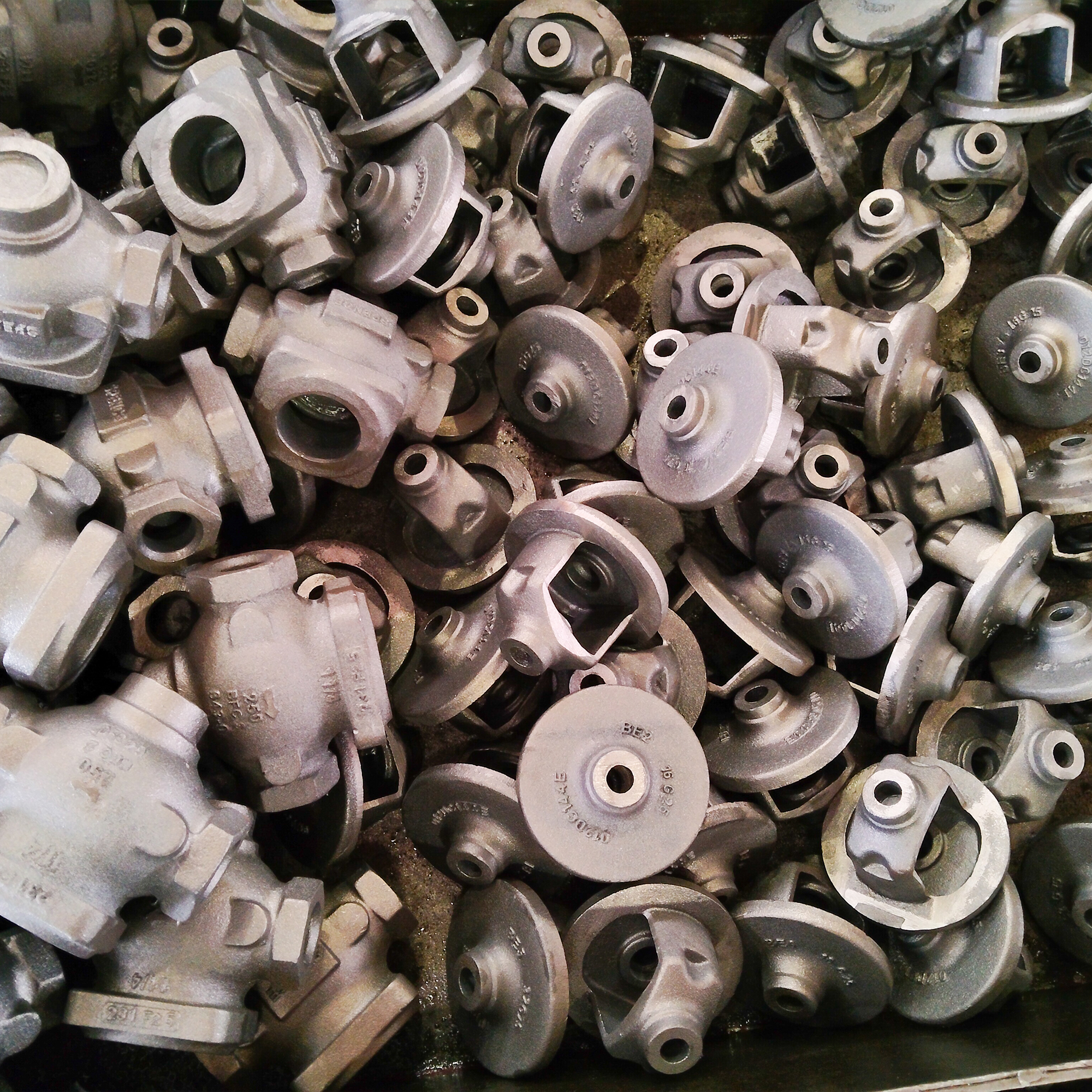

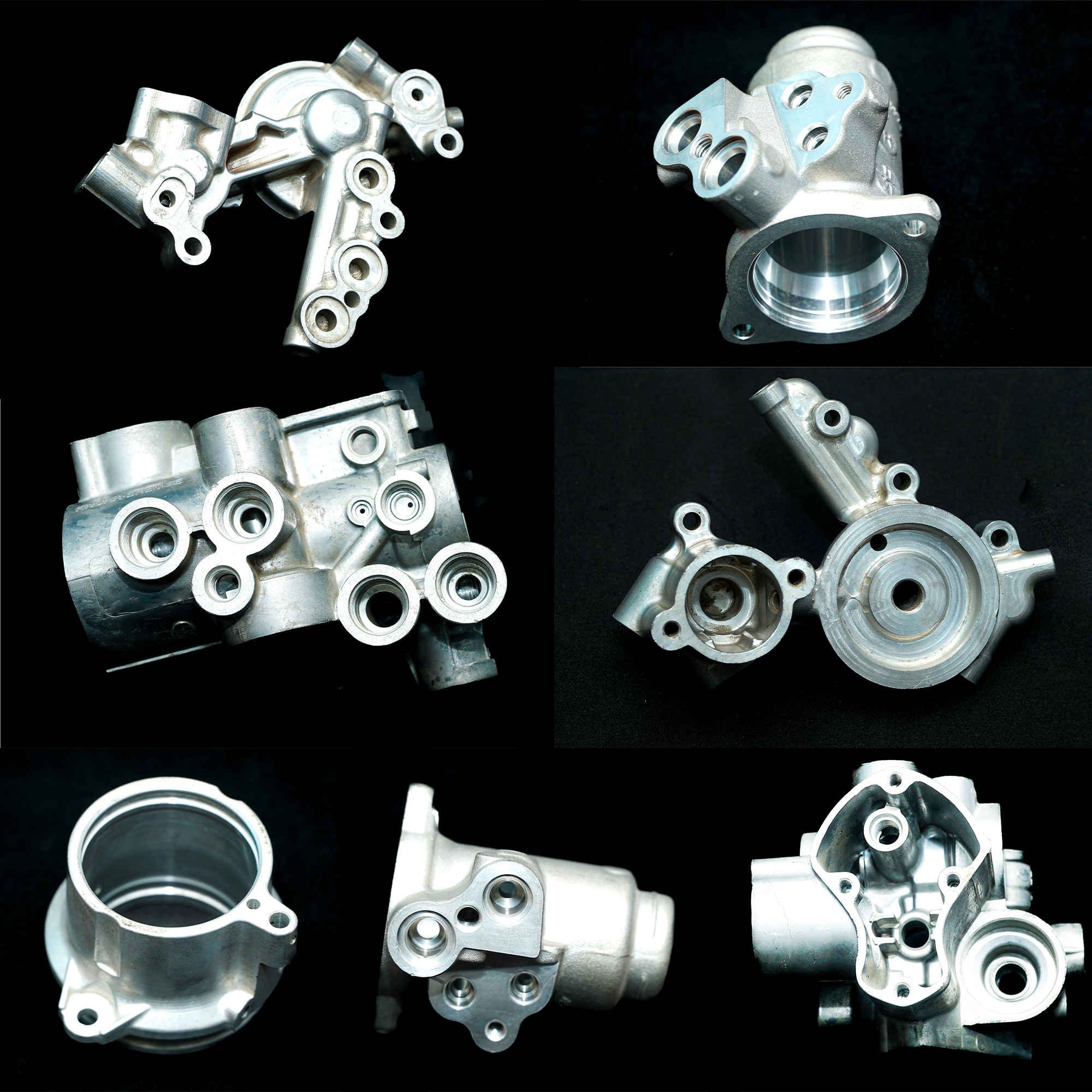

Casting is a foundational manufacturing process where molten metal is poured into a mold to take a desired shape upon solidification. At ONE SOURCE ENGINEERS, we specialize in delivering high-quality casting solutions for both ferrous and non-ferrous metals—engineered to meet the most demanding specifications.

With a wide network of certified foundries and over 60 partner vendors, we offer a full spectrum of casting technologies to suit various industries including automotive, aerospace, hydraulics, construction equipment, and heavy machinery.

Whether you require high-volume production or intricate prototypes, we provide complete solutions from tooling design to finishing—ensuring dimensional accuracy, metallurgical integrity, and cost efficiency.

Why Choose ONE SOURCE ENGINEERS for Casting?

Vendor Consolidation: Access to 20+ specialized casting vendors under one roof

Full Support: From tooling design to post-casting machining and surface finishing

Quality Guaranteed: NDT, X-ray, UT, and MTC available on request

Material Expertise: Cast iron, ductile iron, aluminum, bronze, stainless steel, superalloys

End-to-End Project Handling: For prototypes, batches, and bulk production

OUR ENGINEERING CAPABILITIES

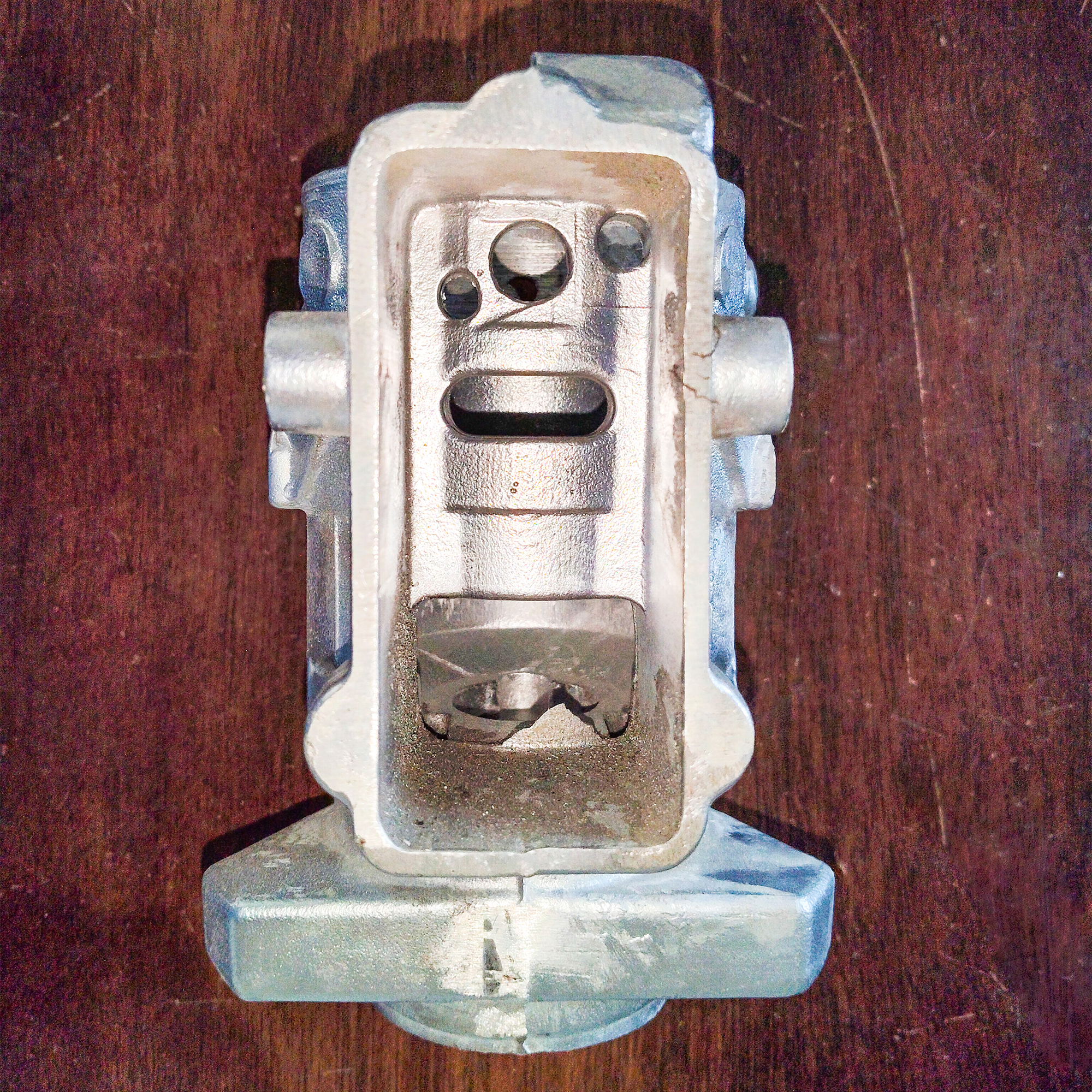

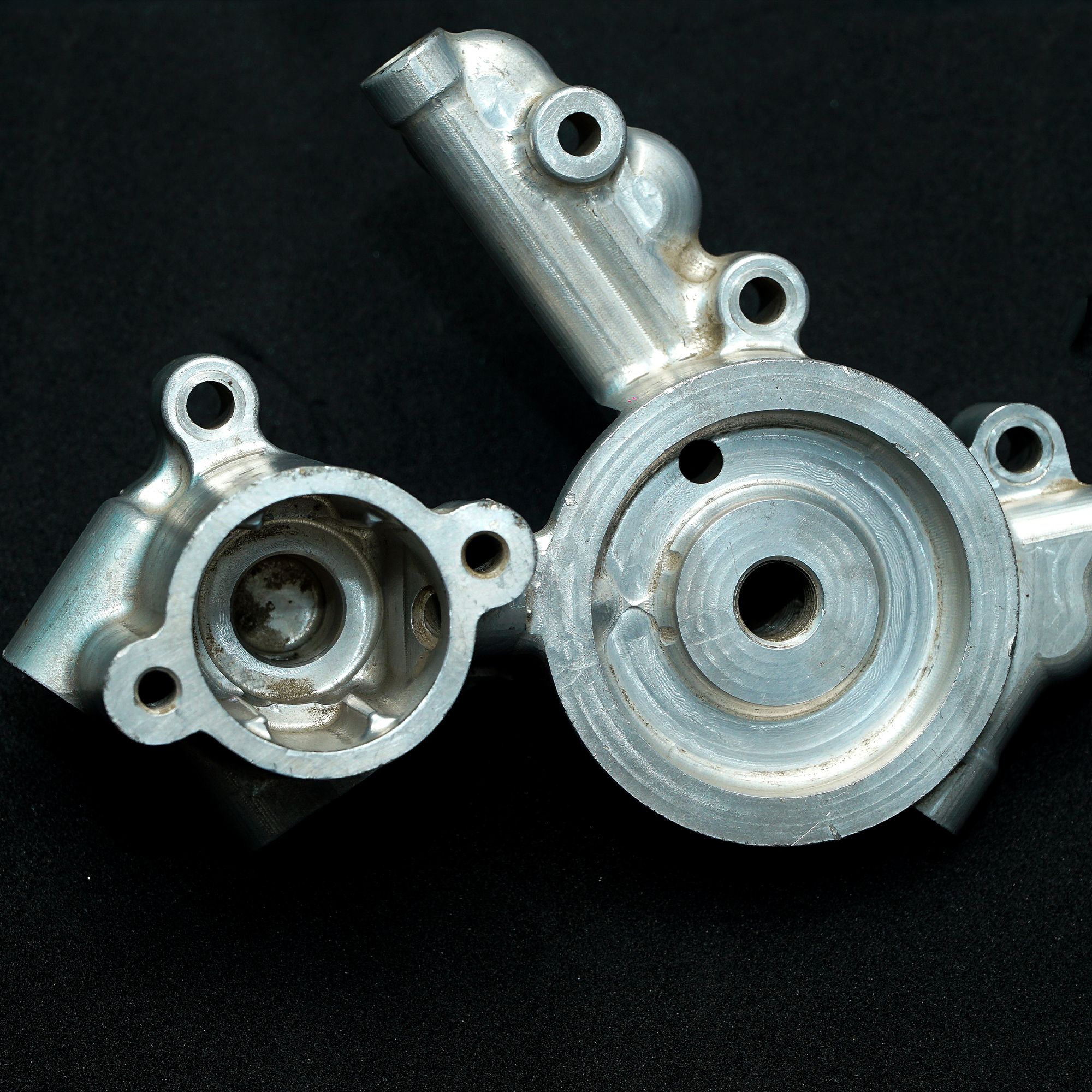

1. SAND CASTING

Sand Casting is one of the oldest and most versatile casting methods, ideal for producing large components with complex geometries. It involves creating a mold cavity using a sand mixture around a pattern.

2. SHELL CASTING

Shell Casting is a precision method that uses a resin-coated sand to create a shell-like mold. It provides better surface finish and accuracy compared to traditional sand casting.

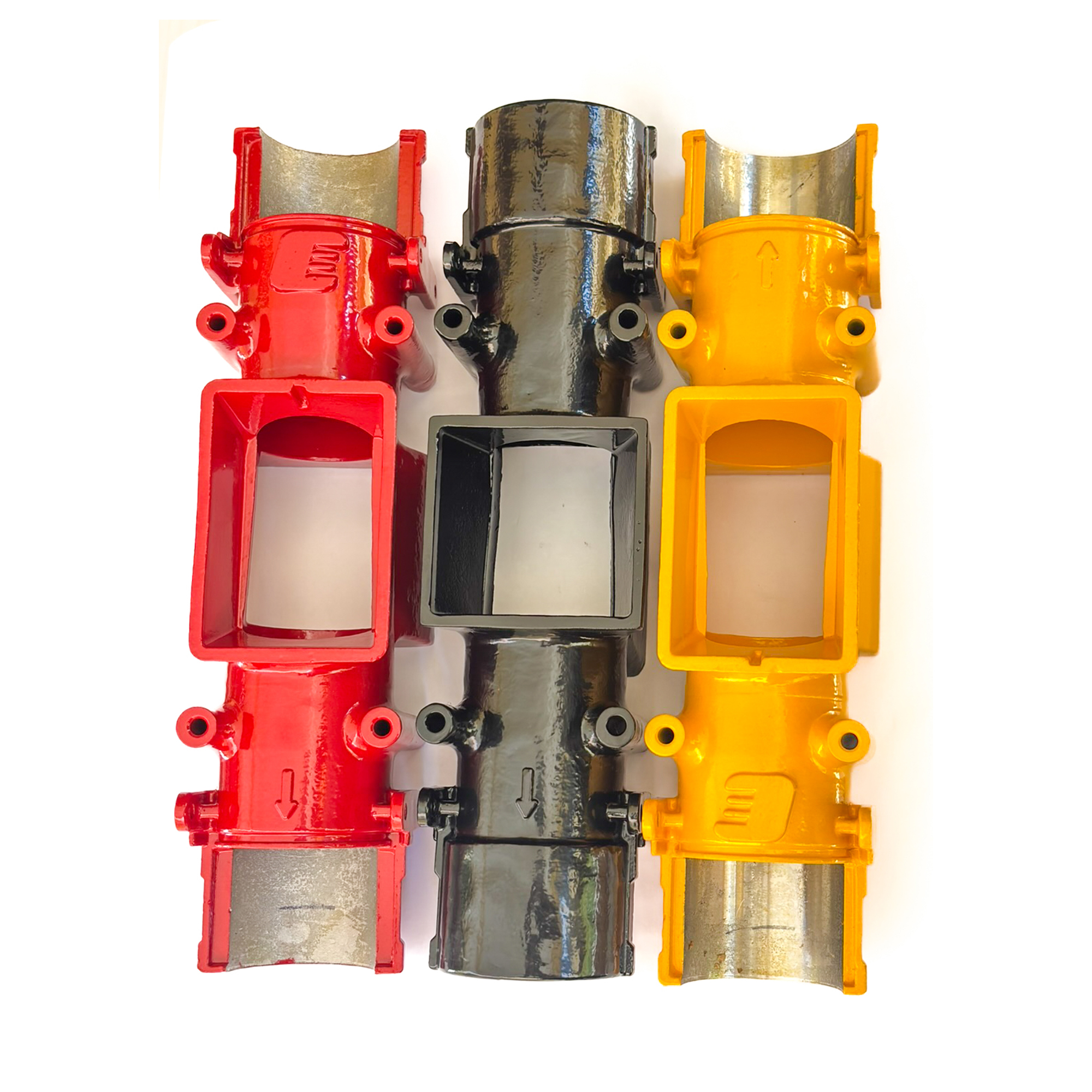

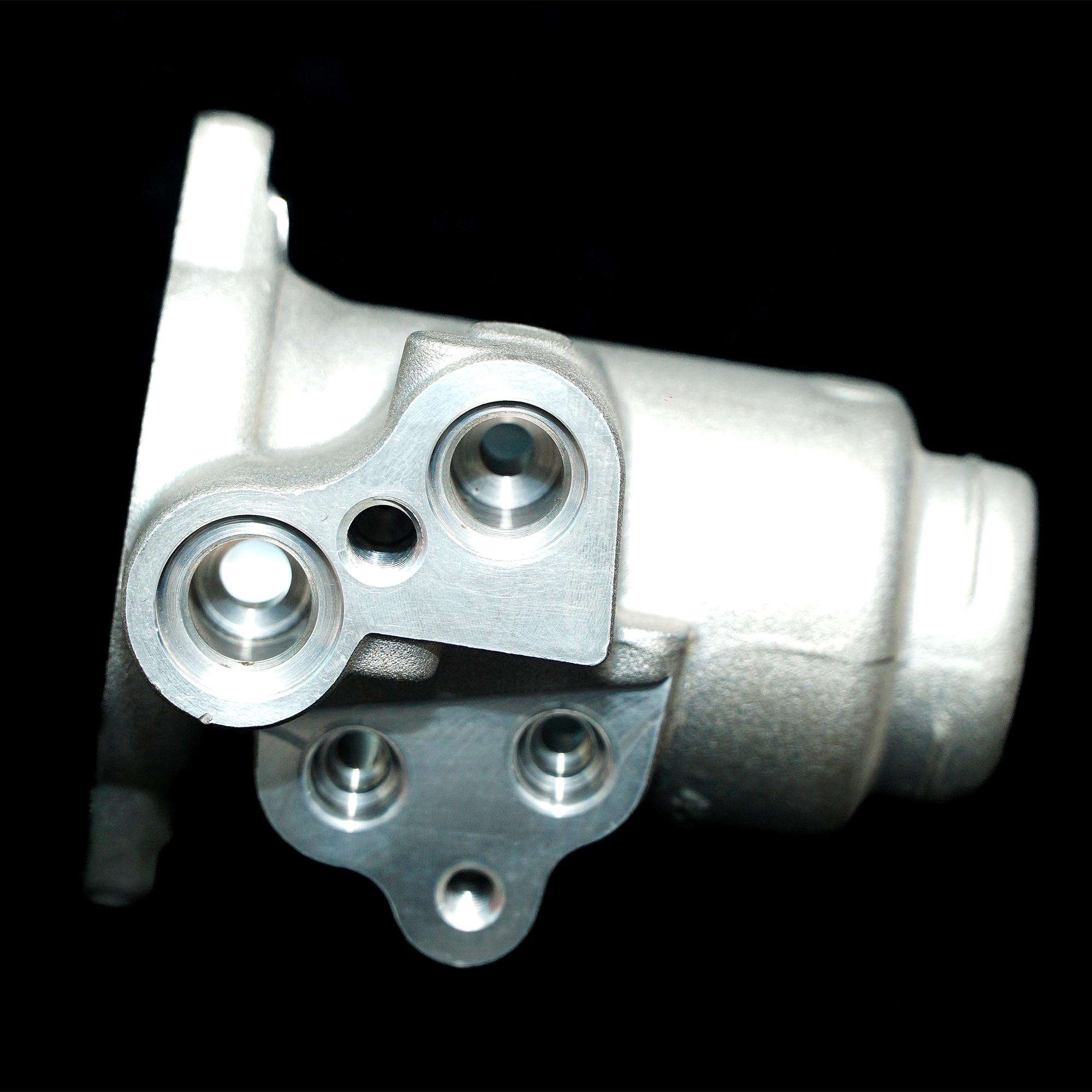

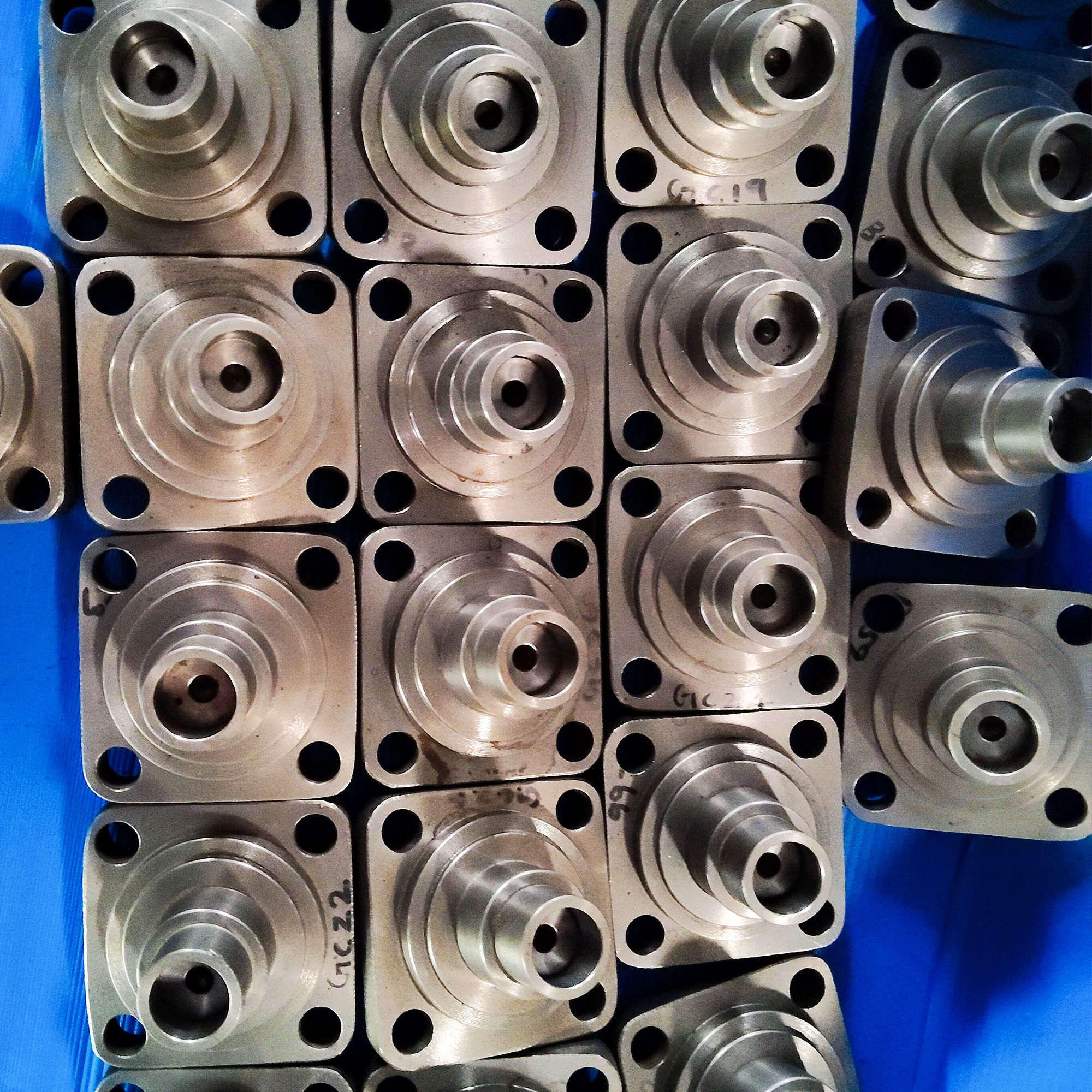

3. GRAVITY DIE CASTING

In Gravity Die Casting, molten metal is poured into a permanent steel or cast iron mold using gravity, without the application of pressure. This method offers a better surface finish and tighter tolerances than sand casting.

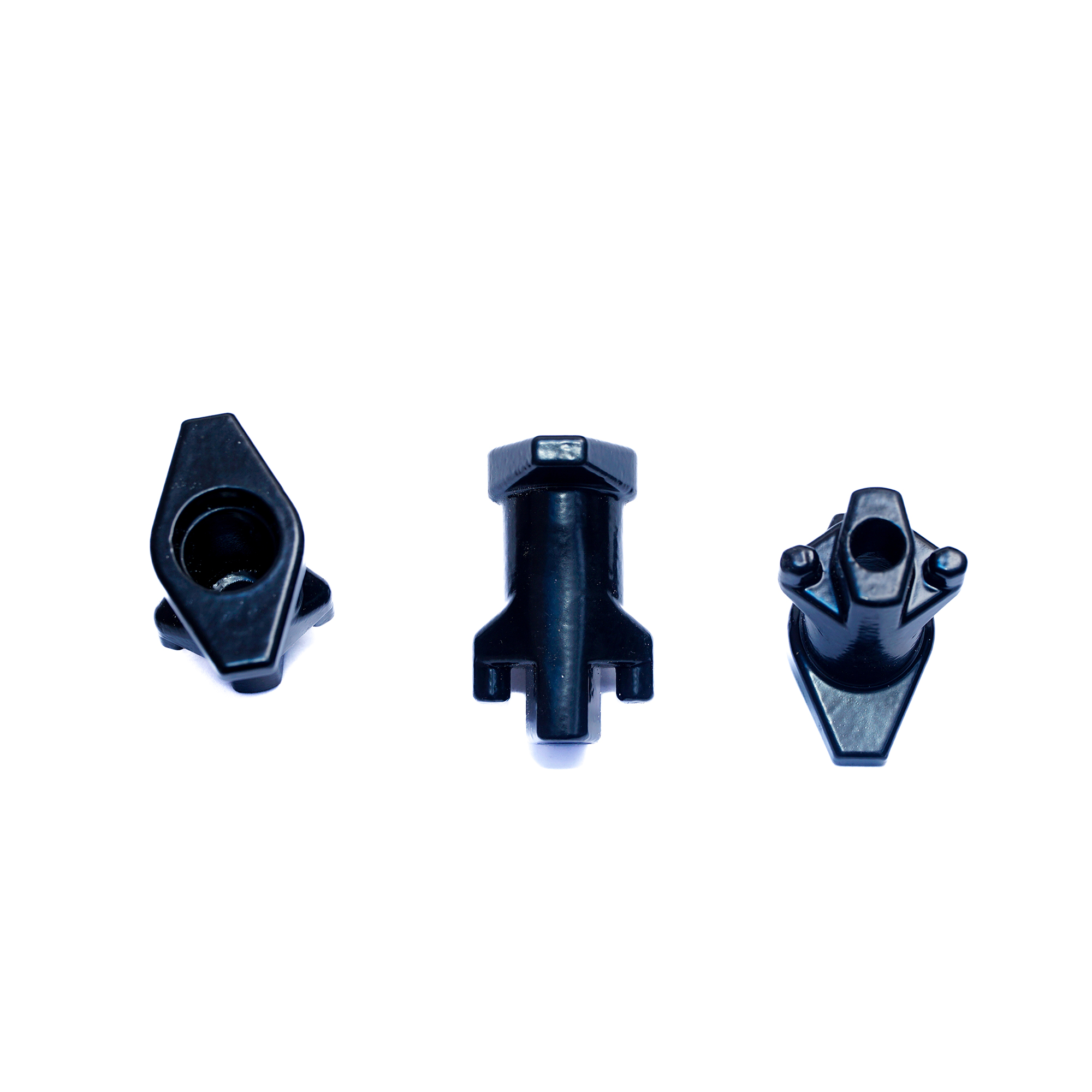

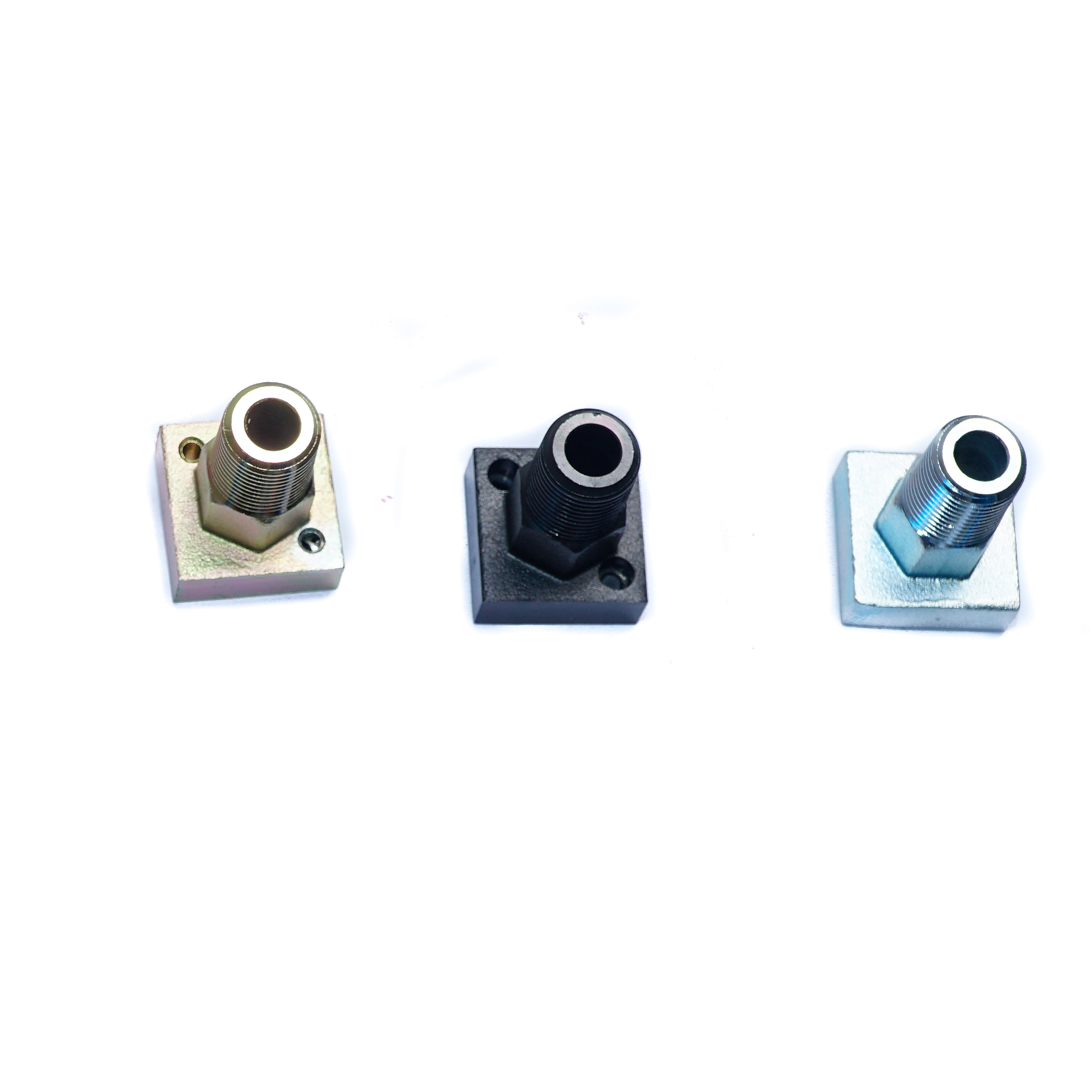

4. PRESSURE DIE CASTING

Pressure Die Casting is a high-speed process where molten metal is injected under high pressure into a metal mold. This results in components with excellent dimensional accuracy, smooth surface finish, and fine detailing.

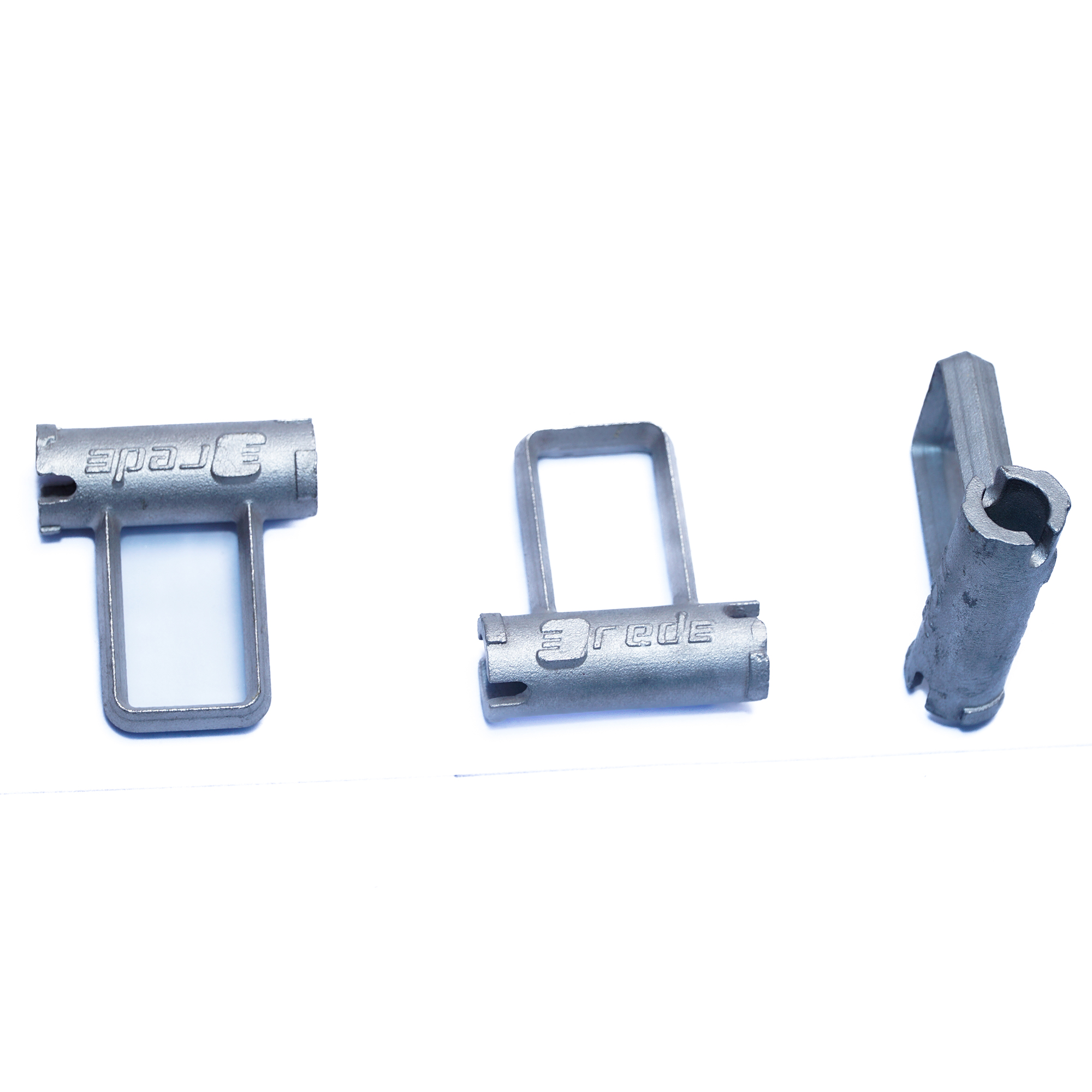

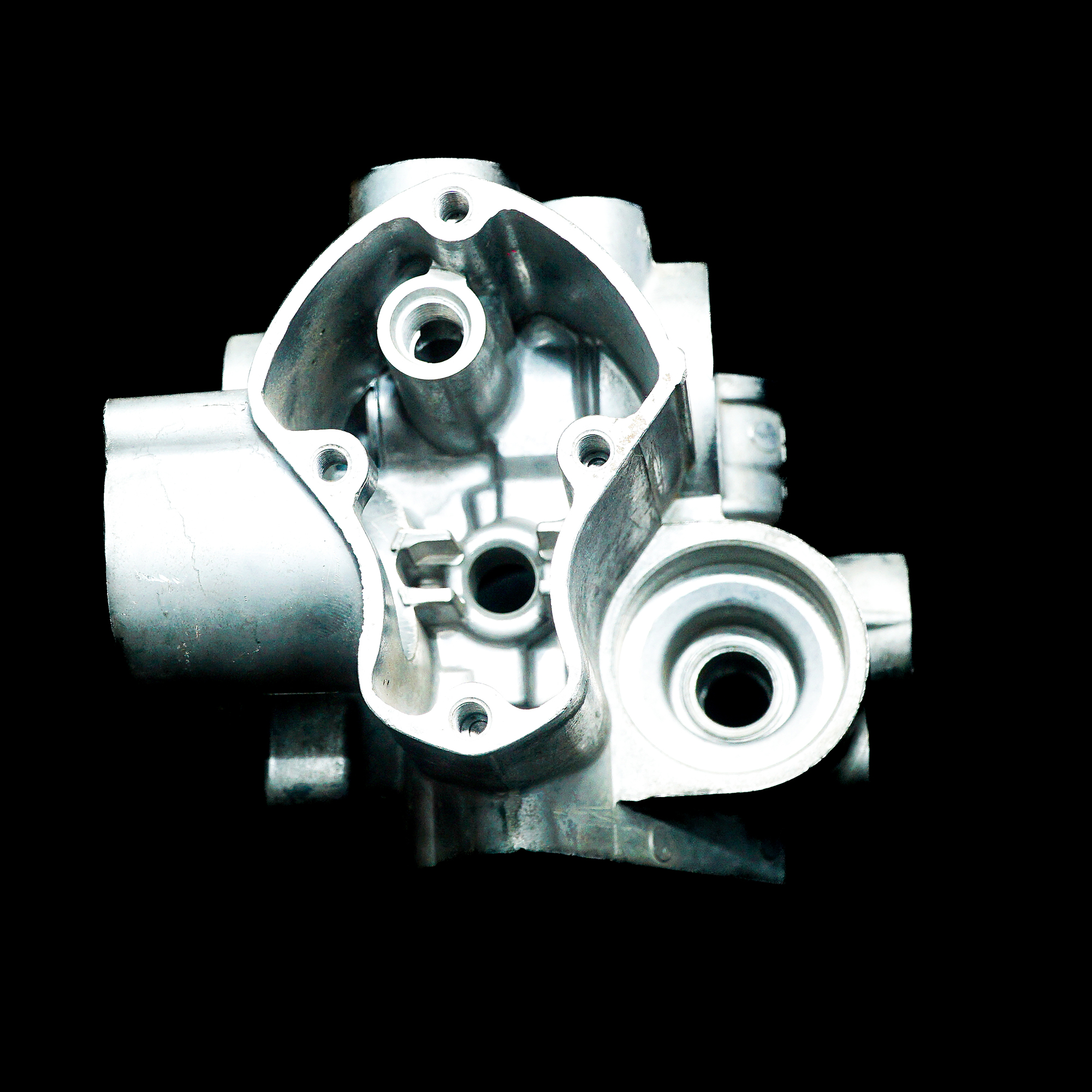

5. INVESTMENT CASTING

Investment Casting is a precision casting technique that uses wax patterns to create detailed molds. Once the wax is melted out and the ceramic shell is formed, molten metal is poured to create near-net-shape parts.